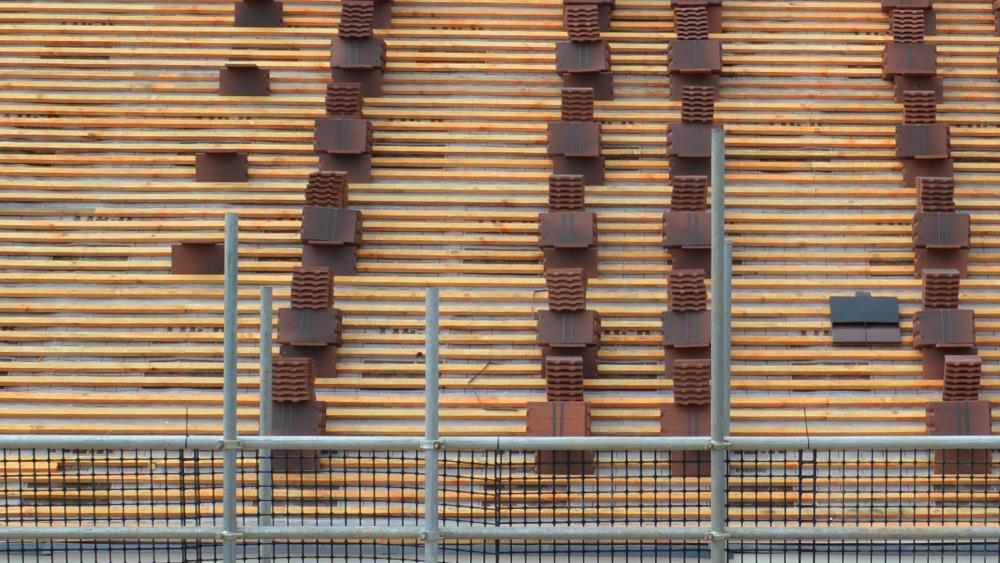

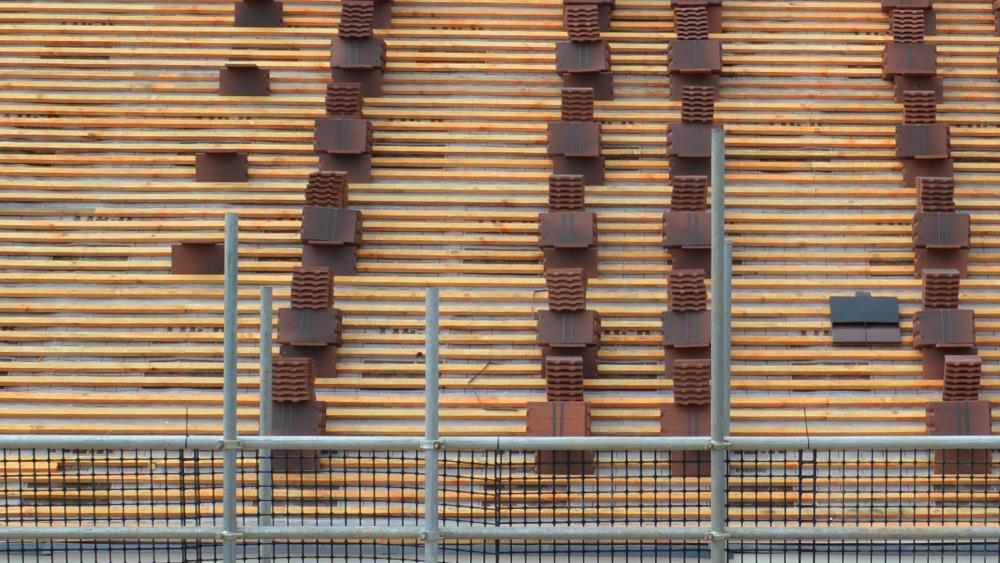

Roofing and builders’ merchants are being encouraged to ask their suppliers whether their timber roofing batten is dipped or pressure-treated with preservatives.

To the naked eye, dipped and pressure-treated battens can look the same, especially if the battens are dyed a specific colour, such as blue. However, the preservative does not penetrate the batten in the same way when the batten is dipped as opposed to pressure-treated, and this can impact the long-term performance of the batten.

SR Timber’s Trading Director Shaun Revill said that the company that supplies the preservative treatment for SR Timber's Premium Gold had been tipped off about the rise in the number of cases of battens being dipped instead of pressure-treated.

“We’re asking merchants, in particular those that are involved with battens, to ask their suppliers a simple question: has it been dipped or pressure-treated?” said Revill.

“Reputable suppliers should be able to answer straight away and explain the process by which preservative is added to the timber – because it is a fascinating process and one that is absolutely vital to producing a finished product that can have a warranty of up to 60 years.

“If they’re still unsure, they could ask their suppliers for treatment certificates, as these stipulate details on how and what the batten has been treated with.

“There is also a specific marking on the side of a length of batten. In our case, we use the Q symbol as a sign of certification for the Q Mark. This denotes that the batten has been independently assessed by third-party quality assurance experts and shows that the grading, preservative treatment, product marking and management processes have all been independently audited and verified by a good third-party body, in our case a UKAS-accredited expert.

“If battens don’t have these markings, this should ring alarm bells for merchants as one of the tell-tale signs of dipped timber.”

SR Timber is concerned that merchants are being hoodwinked into buying battens that are not fit for purpose – and that merchants will therefore let their customers down by supplying an inferior product masquerading as fully graded batten compliant with British Standards.

Revill explained that, as the name suggests, batten dipping is a very quick process that takes just a few minutes, whereas quality batten has the preservative applied in a much longer procedure using low-pressure vacuum or double-vacuum processes. Alternatively, the preservative can be applied using high-pressure vacuum processes.

“Dipping will not achieve the required long-term protection of roofing timber against decay and insect attack. However, controlled-pressure treatments will ensure the correct level of penetration and retention of the wood preservative into the timber, which will provide real confidence in the roofing batten as a key component in any roof design.”

“We’re concerned that if you put dipped and pressure-treated batten side by side, merchants would struggle to tell the difference – which is why we are urging them to ask the question.