New additions offer greater thermal performance across multiple applications

ROCKWOOL has launched Thermal Insulation Cavity Slab 32 and Thermal Frame Slab 32, two dual-purpose products that are the most thermally efficient stone wool insulation currently available in the UK and Ireland.

Made using patented NyRock® technology, the new products have a more efficient fibre structure that is denser and traps more air. This extra air helps slow the transfer of heat further for greater thermal performance and a low lambda (l) rating of 0.032 W/mK.

The first of the range additions is ROCKWOOL Thermal Insulation Cavity Slab 32, which is suitable for masonry cavities. Helping merchants to build flexibility into their inventory and streamline stock requirements, Thermal Insulation Cavity Slab 32 is British Board of Agrément (BBA) certified for both full and partial fill applications[1] and can be used across in new build, renovation and extension projects.

With its 0.032 W/mK thermal conductivity value, Thermal Insulation Cavity Slab 32 offers a 13% improvement in thermal performance versus the company’s existing cavity slab product.[2] This supports builders in meeting the new higher thermal requirements of Approved Document L in England while also providing space saving benefits.

To achieve a U-value of 0.18 W/m²K, builders can use 150mm of Thermal Insulation Cavity Slab 032, depending on the wall build up planned, which is 25mm thinner than the standard stone wool cavity products in a like-for-like application.

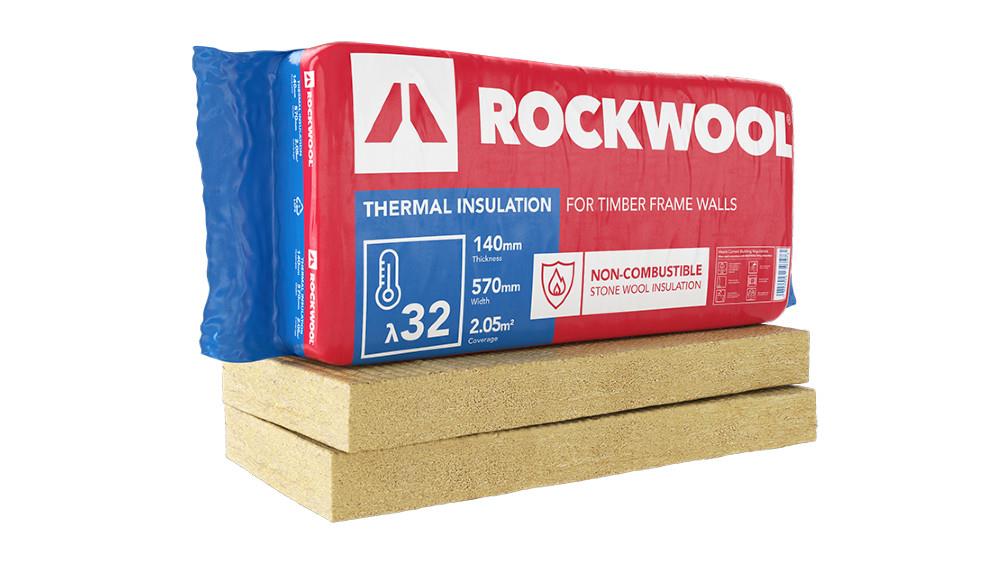

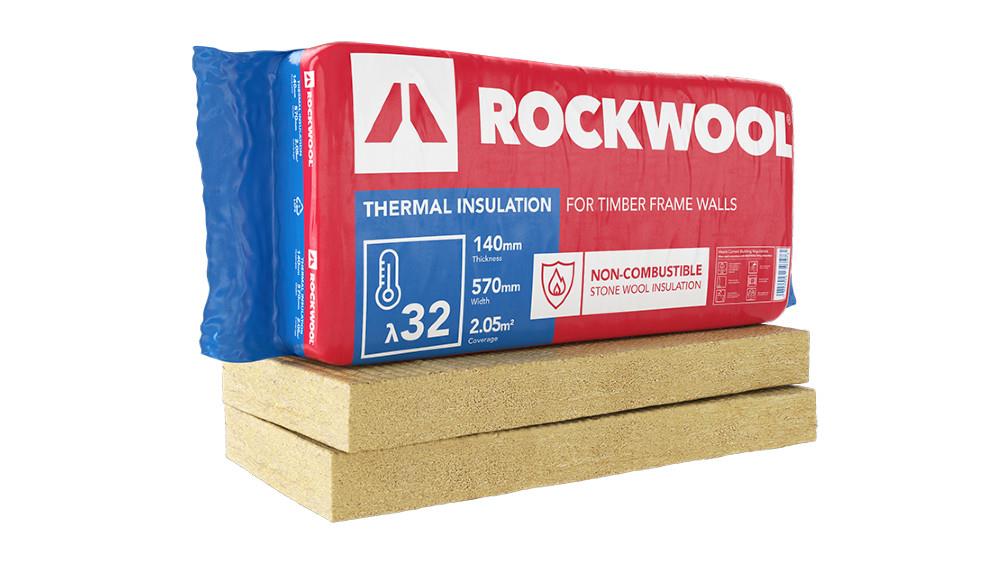

The second extension to the ROCKWOOL Trade Range is Thermal Frame Slab 32. Likewise, this new product has dual applications being purpose-designed for fitting between the studwork of both external timber and light gauge steel frame walls. It can also be used with a brick outer and with or without a service void.

As well as providing upgraded thermal properties, a key benefit of Thermal Insulation Cavity Slab 32 and Thermal Frame Slab 32 is their high density semi-rigid composition. This means they will not slump or sag once fitted and as such, maintain the same thermal and fire resistance properties more than 55 years after installation, according to independent research[3].

Commenting on the extension of the ROCKWOOL Trade Range, Paul Barrett, Head of Product Management at ROCKWOOL UK, said: “The addition of Thermal Insulation Cavity Slab 32 and Thermal Frame Slab 32 enables merchants to offer customers all the benefits of stone wool, including its natural non-combustibility and easy installation, and now with a higher level of thermal performance.”

Both Thermal Insulation Cavity Slab 32 and Thermal Frame Slab 32 can withstand temperatures in excess of 1000°C and achieve the highest Euroclass A1 non-combustible reaction to fire classification. The new additions also deliver acoustic benefits with a composition that helps trap sound waves and dampen vibrations.

Paul continued: “Critically, given the market conditions, both solutions are also backed by a competitive price point, robust availability, flexible delivery support and comprehensive marketing activity.”

To support the launch of its extended Trade Range, ROCKWOOL has updated product packaging, implementing graphic devices and symbols to aid product selection. The manufacturer will now also display the different lambda ratings of its insulation, enabling customers to identify a lower lambda product more easily if they require improved thermal performance.

The launch of ROCKWOOL Thermal Insulation Cavity Slab 32 and Thermal Frame Slab 32 will also be complemented by a multi-channel advertising campaign including updated point-of-sale and enhancements to the ROCKWOOL Demonstration Experience truck.

For more details on Thermal Insulation Cavity Slab 32 and Thermal Frame Slab 32, visit rockwool.com/uk/32