It’s been over 18 months since Boris Johnson announced the first COVID-induced UK lockdown, yet material prices continue to rise.

Hitchcock & King, an experienced builders merchant, is seeing more and more people ask about supply shortages and price rises as they fight to meet demand.

The ripple effects of the pandemic are still impacting supply chains, but it’s not only COVID that has had an effect.

It has been suggested that prices may continue to rise for quite some time, but what increase have they already experienced in the past year?

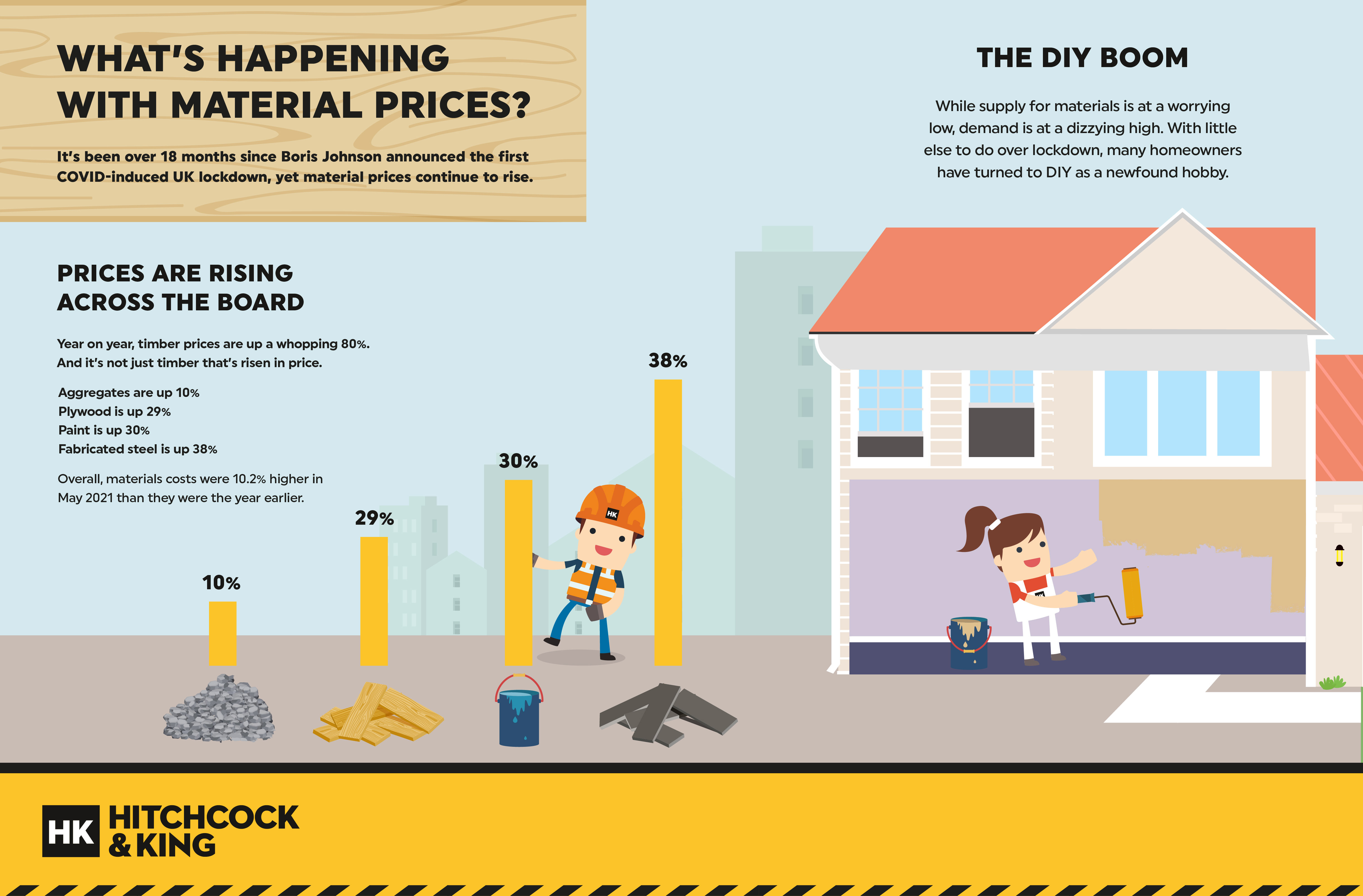

Prices are rising across the board

Timber prices have been rising steadily since May 2020, and were up again one whole year later, according to the Department for Business, Energy and Industrial Strategy (BEIS). Year on year, timber prices are up a whopping 80%.

And it’s not just timber that’s risen in price.

Overall, materials costs were 10.2% higher in May 2021 than they were the year earlier.

So what exactly has caused these prices to rise so much?

The DIY Boom

While supply for materials is at a worrying low, demand is at a dizzying high. With little else to do over lockdown, and a new appriciation of their living quarters as they had to spend some much more time there, many homeowners have turned to DIY as a newfound hobby.

From a lick of paint to a new shelf, lockdown has ignited the DIYer inside of all of us. While it may have been good for our mental health, everyone’s latest hobby has put a strain on an already dwindling market supply.

The Brexit Bust

Amid the chaos of the pandemic was another major event: Brexit.

Leaving the European Union has altered international demand and shipping costs, which is slowing deliveries and, therefore, reducing supply.

Plus, many businesses have stockpiled, and are continuing to stockpile materials in anticipation of a further Brexit-induced supply shock. This has perpetuated demand during a period that is already seeing significant increases in the number of orders.

Legislation changes have also put a strain on the supply and cost of raw materials. For example, heat-treated materials like pallets and crate boxes are increasingly in demand due to changes in legislation on UK to EU shipments using wooden packaging.

The COVID Bedlam

The effects of the pandemic are still being felt to this day. Reduced staff, border closures, and financial difficulties have all contributed to inefficient supply chains. Shipping costs have also increased, which has placed additional financial strain on suppliers.

These price issues are affecting merchants nationwide. While outside of their control, many merchants are doing all they can to increase supply and match demand while staying transparent with their customers.